There are three reasons why I wanted to do a home made hard case for my uke:

- I’m clumsy enough to be scared of breaking my uke in a gig bag

- Hard cases are expensive and I did not want to spend that money on it

- I like to build this kind of things

The material cost was 13€/£10/$16 (in July 2012). So very very cheap but I had some things already in the house/garage. I got the idea from the box my ukulele came in. Then I looked at similar projects online, but all were converted ukulele cardboard boxes (e.g. Ukulele box case – cheap easy way to recycle your uke box into a case). Unfortunately cardboard is not very sturdy, so I made a wooden one.

Material

- (waterproof) plywood 6mm (the thicker the heavier) – 9€

- wood glue

- wooden strip (to harden the joints) – had some left overs from window frames

- wood screws (the smallest I could find were 9.5mm x 3mm and I filed them afterwards) – 1.5€

- 2 hinges – 1€

- 2 metal latches to close the case – 1.5€

- cloth – in my case old pants

- insulation foam 1cm thick (for laminate floor) – the pieces that I had at home

- double sided tape to stick the cloth to the insulation foam and then to the case

- a handle and its hardware – I used a leather one from an old suitcase

Tools (other tools can be used as replacement for any of the below):

- belt sander (to sand the plywood and excess of side boards as they were a few mm longer for this purpose – sand belt 120)

- craft saw (to cut out the grooves for hinges and clips)

- screwdriver

- angle grinder (for filing the screws)

- varnish/paint/laquer and brush (or nothing if raw wood is preferred or if it will be covered in tweed or some similar material)

- clips (to hold pieces together when gluing)

- scissors (cutting the cloth, tape and insulation foam)

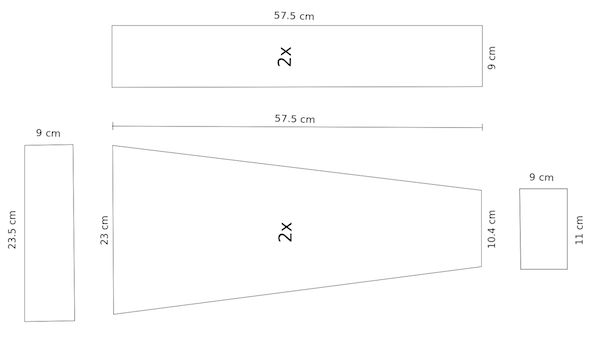

I cut the wood at the local workshop as I don’t have the appropriate tools at home. The below measures suit my soprano ukulele (friction tuners). Bear in mind that the top and bottom need to be wide as or more than the width of uke + 2 x insulation + 2 x plywood width. Just trace the uke on a paper and add extra width to get the right dimensions. The sides were cut a bit longer for purpose and I needed to sand them to the right sizes and angles after the box was glued.

The case is just a bit under 2kg (4.4lbs) in weight.

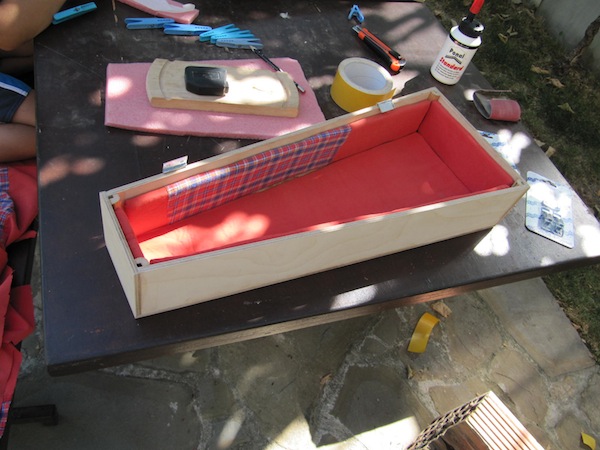

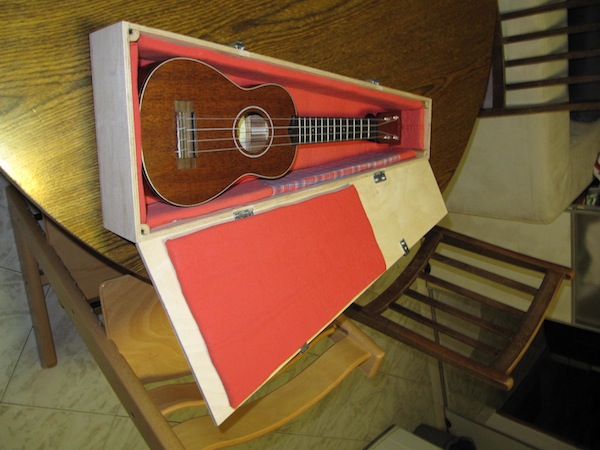

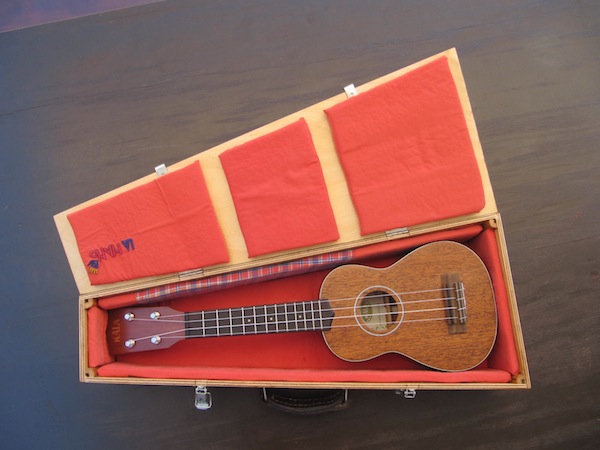

The whole process can be seen from below photos.

EDIT: I just found a similar but more sophisticated DIY case. The brass hardware looks nicer (I couldn’t find it in my local hw store). And this guy used rubber foam and velvet material. Very nice case indeed!